Laser Engraving Software Free Download

For Grbl, Benbox and Eleks Maker Laser Engraving systems. Image to G-Code Conversion. Supports JPEG or BMP import (up to 24-bit color). Greyscale (S-value) and. Free Laser Engraving. Menu HOME; DOWNLOAD; USAGE. With image engraving. Professional machine are bundled with their own software. Figure: Gearbest.com Laser Engraving Machine (baseboard not included)If you have already assembled your Eleks Laser, skip down to the Software Instructions. Unlike professional laser machines, which are used for cutting the challenging materials such as metals, a DIY Laser Engraver use a low to medium power laser that can engrave or cut only thin materials like leather, plywood, acrylic, cardboard.

1-Touch Laser Photo ™ 1-Touch Laser Picture ™ is definitely an revolutionary product for switching digital photos (BMP, JPEG, PNG or TlFF forms) into bitmap data files that can become used to indelibly tag or engrave the picture into materials such as tough wood, rock or metallic to generate high value items. This transforms an normal photograph into a expert quality engraving. Prior to 1-Touch this was possible just by testing with halftone displays, dithering patterns, and laser settings - an expensive and time consuming methodology.

1-Touch automates this process and offers these benefits:. Guia quatro rodas rodoviario 2013 download. Optimize Come back on Investment decision 1-Touch Laser Picture automatically turns digital photos to optimized bitmaps, conserving both time and materials. High Quality Results Picture processing software created by the specialists at ULS delivers professional high quality laser marking and engraving outcomes every time.

Broadest Range of Materials Compatibility Photographs can end up being laser marked or laser engraved onto 100s of components using the optimized process setting computed by the ULS Intelligent Components Database. Normal Software Updates New materials are included to 1-Touch Laser Photograph every quarter. Intuitive Consumer User interface All that'h needed are three easy steps to change a electronic picture to a professionaI-quality engraving. Have Alone Software 1-Contact Laser Photograph is compatible with all brands of laser systems. How to Create Great Quality Laser Engraved Pictures 1-Contact Laser Image transforms digital photographs into individual bit raster graphics that are usually suitable for laser márking and engraving. Thé software will this by using the bitmap screen that will be the almost all ideal for the materials that is being designated or imprinted. 1-Touch also instantly applies image enhancements that have been developed by ULS.

The completed bitmap will be after that exported to the laser program for laser márking or laser éngraving the chosen material. Photo imprinted onto cherry real wood using 1-Touch Laser Picture Optimize Come back on Expense 1-Contact Laser Photo removes the need to test with bitmap screens and image improvements. This saves period and eliminates lost material. Rather of repeated cycles of test and mistake, 1-Contact Laser Photograph users merely action through the process outlined above to attain professional high quality laser engraving outcomes. This process delivers completed products quickly, thereby improving the return on expenditure for the laser system owner. High Quality Results A group of picture processing specialists, materials researchers, and software engineers at ULS worked well together to generate 1-Contact Laser Photograph, the industry's premier laser photograph engraving software deal. The software automatically is applicable the perfect halftone display screen for each materials.

The software also automatically can be applied image enhancements. Broadest Variety of Material Compatibility 1-Contact Laser Image functions seamlessly with the ULS Materials Database to permit pictures to end up being laser noted or laser engraved onto 100s of materials. Here are usually just a few examples. Photos engraved onto nine various materials making use of 1-Contact Laser Photograph Regular Software program Updates Laser beam material processing technology will be constantly evolving.

1-Touch Laser Picture keeps speed with these developments by including new components every quarter. Intuitive Consumer Interface Customers worldwide have got confirmed that 1-Touch Laser Photo is certainly the almost all user pleasant imaging software in the laser refinement business.

The intuitive user user interface along with automated image processing allow also novice users to create professional quality results. Have Alone Software 1-Contact Laser Photo operates separately of the laser program handle software. This enables it to become used with any brand of laser program.

. Edition 9.1. Rev 1, released October 18, 2016 (size = 383MW zipped) Download includes Vision Show, Vision Expert and Eyesight Pro. Not really suitable with 64-little bit Windows XP.

Edition 8.0. Rev 1, launched Nov 10, 2010 (dimension = 302MM zipped) Not really suitable with Home windows 10. Edition 7.1. Rev 1, launched April 9, 2008 (size = 327MB zipped). Not compatible with Home windows 8 or 10. Version 6.1. Rev 17, released December 23, 2004 (size = 230MM zipped).

Not really compatible with Windows 7,8, or 10. Version 5, rev 6.4, released Sept 26 2002 (size = 246MM zipped).

Not compatible with Vista or Home windows 7,8, or 10. Download this file to install an online test version of Vision Express, Eyesight Specialist and Pro.

(dimension = 349MM zipped). Version 1.31ZTimes, build 67a, full download (size = 17MB zipped) This will not really upgrade Vision DOS.

Not really suitable with any 64-little bit Home windows or Home windows 10 (only certain configuration settings are suitable with 32-little bit Windows 7 or 8). Nowadays to understand more about, or call 1-888-637-1737. Drivers Utilities.

Connection Manager for setting up IP address on Eyesight Show, VE810 and Series 4 controllers. Released December 9, 2013 (dimension = 12MW zipped). Work Name Machine, Connection Supervisor, and additional utilities. Edition 4.6.328.2 Released July 1, 2016 (size = 111MT zipped). Work Server, Device Connections, and other utilities.

(Gain Vista, Gain XP Get 2000) Download this for the most recent Eyesight Pro dongle car owner for Windows 2000, Windows XP and Windows Windows vista. (Home windows XP, Vista, 7 8 only) Download this for the latest Vision Pro dongle car owner for Home windows XP, Vista, 7 and 8. (Windows 10 only) Download this for the latest Eyesight Pro dongle drivers for Windows 10. All of the Vision Pro Format Fonts downloadable. AIl of the Vision Professional Engraving Fonts downIoadable.

All of thé Eyesight Professional Clipart downloadable Firmware.

Physique: Gearbest.com Laser Engraving Device (baseboard not included) If you have already assembled your Eleks Laser beam, skip out on down to the Software Instructions stage. Hardware Building This record expands on the details of the lnstructable below: “ How tó: Laser beam engraver!” by MakerBox Incorporating some extra hints on construction, as properly as offering more information on wires and setting up and using the Benbox software drivers.

Please find the over Instructable for the equipment construction information. There are several video clips and tutorials on creating the Eleks Laser beam, particularly the GearBest (and Banggood) models. But many lack details, particularly with the software setup. GearBest: Banggood.

Below are some suggestions and suggestions for developing your Gearbest ór Banggood Eleks Laser beam Engraver. The Instructable above provides the details, but I discovered these products as I proceeded to go thru the actions in their guide. Examine through these and after that jump to their tutorial. Do not over tighten fat bolts to maintain from breaking. (Hopefully, obvious!) In step 2: Body Assembly Make use of the 1cmichael mounting bolts with nuts on the body.

Not really the 1.2cmichael or 1.5cm mounting bolts. In stage 3: X-Carriage Use a 3cmichael bolt, acrylic bracket, plastic spacer, washer, bearing, washing machine, nut for each showing assembly. Orient the Stepper with gear with wiring connector towards the bearings. (image 1) Build the second x buggy as a reflection image of the very first (image 2) In Step 4: Laser beam Set up Attach the Laser beam and the Stepper with gear to the acrylic items before putting together the lengthy screws and bearings (image 3 4) The kit incorporated two plastic material guide covers to course the cables along the outside framework, but you have to set up the wires BEFORE you build the steppers onto the body.

But it's i9000 mainly appearance. In Action 6: Belt Assembly Install the center (laser mind) belt first. Use the 1.2cmeters mounting bolts and nut products. Do not really cut the belt until you possess it adjusted.

Feed the whole belt thru the 2nd acrylic securer. Tighten fastener and slide the stepper set up up and down the railroad.

It should traveling smoothly and the belt should remain anxious on the stepper equipment. When ready to reduce, keep at least a fifty percent inches or só sticking out óf the acrylic fasténers so you cán adjust tension. Don't reduce too brief! There is definitely about 6 in . of spare beIt available after aIl the installation. Thé “How to: Laser engraver!” Instructable is certainly great for the equipment design, but a little bit slim for the wires and on the software aspect. Cable your Laser Engraver making use of the above diagram.

Back button motor is definitely laser set up stepper.Y1 Y2 are the two part steppers. Make use of the spiral plastic tube for the Laser and its Stepper wire. Path the Y1 Y2 Stepper cables below the framework if you did not remember to wire them formerly. The kit incorporated two plastic guide addresses to route the wires along the framework, but you have got to set up the wires BEFORE you build the steppers onto the framework. But it'h mainly good looks. Wait on plugging in the USB wire until after the software set up. The below software packages currently appear to end up being the exact same versions.

I have got the GearBest, so set up that edition known as: “EleksLaser software.diddly” A new) From the: '● If you desire to download the tough drivers, please.' M) Or From thé: “The software wé possess upload it to thé netdisk, ánd its downloading hyperlink is usually: “ D) It is also obtainable at These should all become edition 3.7.99 from what I saw. Unpack the Eleks Laser beam software from either above site.

Navigate to the Eleks Laser Benbox directory website and double click benbox.exe 3. It needs Manager to install. I effectively set up on Windows 10.

(but see step 6 7 below) 5. Keep the defaults for the drivers. Wear't bother installing their “Driver.exe” 6.

Best Laser Engraving Software

NOTE: In purchase to get a working USB driver, I discovered that installing the Arduino IDE was the greatest bet. Setting up the IDE will automatically install a good Windows 10 car owner. But, the Car owner.exe install will work with Home windows 10. So, if you perform not notice the COM port dynamic for your Laser beam (using Windows Device Supervisor ->Slots (C0M LPT) ->USB-SERlAL CH340 (COMXX) ) then go forward and install Drivers.exe as Manager. During the BenBox installation, Windows Firewall requests opening interface 7683 on your local Computer. Select Allow “Personal” network (not really Community). This can be enabling the BenBox GUI to speak to the BenBox (laserdaemon) assistance (both working in your area on your Personal computer).

It is definitely NOT opening your router firewaIl to the Web. No worry unless your Personal computer is seated directly on the Public Web (i.e. In á DMZ) or á general public (unprotected) Wi-fi network. Your trojan security may notify. As longer as you down loaded the software fróm Gearbest or BangGóod, you are just viewing a fake positive.

Scary, but not a actual issue. Notice, some state to delete a document called laserdaemon.exe but I found that if I did, I could simply no longer obtain the driver COM port to show up in BenBox. (Wireshark demonstrated a link between Benbox.éxe laserdaemon.éxe, but no information is exceeded.) If you don't experience safe, you could operate Benbox in á VirtualBox VM operating Home windows. Procmon displays laserdaemon.exe reading through the Registry, but doesn'capital t show up to compose anything.

Benbox folks state its utilized for motorist and not malware.:-/ 8. After installing, restart your personal computer. It provides also been suggested that you arranged the system to Operate As Owner: Best click on the Benbox Icon, select Attributes, click on Compatibility tabs, and choose Run this program as an Administrator. (see image) This allows it to conserve any configurations. Take note: this appears to just affect particular installation of benbox. I believe related to what your security degree for your consumer id is definitely.

But establishing it on appears okay. You can now connect in your USB cable and 12v energy wire to the Laser Engraver.

Keep the 12v energy OFF originally. (the remaining red Strength button on the Eleks controller not stressed out) The 12v operates the steppers and laser. Not really needed for the initial setup. As soon as ready, dual click on the BenBox icon on your desktop. NOTE: I found that BenBox doesn't always detect the Laser Engraver USB COM port the 1st period it starts.

Just give up BenBox and after that reboot it once again. Seems to work great the 2nd time!

Engraving Software

Established the LANGUAGE by hitting on the small banner in top left part and go for Durante (or appropriate) (notice photograph) 12. Next, choose the Menus image (the icon with the 3 horizontal bars) and choose the Serial Slot for your Iaser.

If you do not discover your Laser's COM interface, also after unplugging ánd re-plugging, then your Firewall may be blocking the 'laserdaemon.exe' background process. Temporarily switch off your Home windows Firewall from the Handle Panel. Run Benbox.exe as Manager. Stop it once again and then Run it a second time. This time, look for the Serial Port COM for the Laser. Right now you can switch the Firewall back on (you can make use of the 'Use Recommended Settings' key, if inquired.). This should upgrade the Firewall rules for the laserdaemon procedure so should end up being fine today.

Do it again this process if a Home windows update causes the Benbox to stop showing the COM slot once again. You must set up firmware into thé Arduino Nano. Be certain your Laser engraver is usually connected in to strength and USB. Keep the 12v energy switch OFF. Choose the “light bolt” symbol to add HEX Range of motion. Choose the COM port (most likely the base 1 on the dropdown list) NOTE: If you have got a issue then make use of the ALTERNATE FIRMWARE Directions, next web page.

Select NANO gadget 5. Click Choose Firmware and get around to the Eleks Laser Benbox Range of motion listing and choose the Eleks-Benbox.hex file (aka. 'LX.hex') and click the OK key (glowing blue check tag box). If you have problems with the Benbox Firmware set up, try out the adhering to: a. Quit Benbox c.

Download XLoader ánd LX-Nano héx file: d. Run XLoader and choose the LX-Nano hex document (aka LX.hex), COM port for your Nano(In328), 57600 baud (image) d. Begin Benbox once again. You should now discover the COM interface available in the Menus->Serial Port drop-down. (Menu icon is usually 3 horizontal ranges under “ Benbox Laser beam Engraver” text message). Above screenshots display the BenBox instructions.

Note that some commands are not really accessible (blacked out on screenshot). Particularly, Laser Strength is not avail. It is certainly always Utmost. Make use of Engraving Acceleration and Burning up Time to manage. Be sure your setting match up those in the photograph as a beginning point.

Pull a right collection an 'in .' or two ón your scréen using the gréen drawing tool bár on the Ieft. This is definitely just for a fast test. To remove, right-click to end drawing setting then still left mouse drag over your series to select and hit Delete essential.

Choose the Menu options proven below. Notice the tabs for the other options. Place a piece of cardboard boxes or color papers on laser mattress. I recommend placing a piece of 8” back button 12” fibers board or plywood on the bed and after that spot your test materials on top it and place under the Iaser. You will burn off your tabletop or desk otherwise!

Place ON YOUR LASER GLASSES! NO Children NEARBY!

A 500MW or higher Laser will be DANGEROUS. Melts away skin, places out eye, etc.!! Treat this like an Arc Welder with sets off traveling by air all over the area! Change on the Energy push key on the Eleks controller plank (discover the wires diagram formerly) 4.

Concentrate the Laser by pushing the Weak Laser key on the controller and adjust for sharp beam. It will be a small figure out when concentrated. Perform NOT leave the Poor laser switch frustrated for even more than 30 secs. I found that I could change it off ánd the laser still glowed. As soon as focused, I flipped off the Power key to obtain it to stop lasing. If away from, convert the Strength button back ON.

Notice that there are usually LASER controls on the Benbox menus bar: OFF d/a ON FULL Momentary On 7. Click on the Environment friendly Play button. The Laser should change on and burn off a collection then change off. I change off the Energy key on the control afterwards, simply to be secure! If everything functions, then following arrives the real fun understanding the changes.

If troubles, leap to the final step: Troubleshooting. There is some limited photo adjustment tools that are usually a little bit hidden. Load a black whitened or grayscale JPG image (click on the folder icon and navigate to an picture). Once loaded, Click on the image to select it and observe a filled collection around it. Look in the higher right corner for a small blue container.

You may need to move the image down a little bit. Click on the small blue box. A screen will open up that allows you to change, hand mirror, or alter grayscale. Note that as soon as you utilize a transformation, the Stop or Back button buttons don't revert the image. You have to just reload the image (back to action 1 above). Resizing pictures by dragging is probable, but not very clean. Its best to resize your pictures making use of a images system and after that load them.

(added 12/2017). This part gets a labor in persistence and slow, methodical work. When understanding, I discovered that it is definitely best to alter settings ONE AT A Period, normally you can't tell which one in fact worked. Each materials will be different, so write down the values as you find them. Initial configurations and ideals demonstrated in image. Hints Suggestions. Consider doubling or halving the ideals of Acceleration.

1600 will get you a light engrave in (assuming 2w) 400 slashes the slim cardstock (integrated with laser package). Changing TIME does not have got much impact for me. Use split, free InkScape program to convert SVG files to DXF. Accuracy is managed by PPM setting. 160.0 increases precision (kinda!) but halves size, so resize images by 2x.

BenBox sketching region rulers are in mm. 25mmichael = 1 in . (approx.). Energy off between uses up to decrease stepper heating system (and enhance safety!).

Don't engrave/reduce any type plastic materials without good ventilation. Engraving elaborate images in your bed room will arranged off fire alarms!:-0. ALWAYS Remember your Laser beam Eyeglasses! No kids w/o eyeglasses. Do not stay your fingernail under beam it WILL bore a small pin thru!

And harm like hell! These Laser Engravers are usually relatively inexpensive, but they do require time and work, so numerous items can proceed wrong. Your greatest wager for troubleshooting is the great benboxlaser.us community forum: Assist!

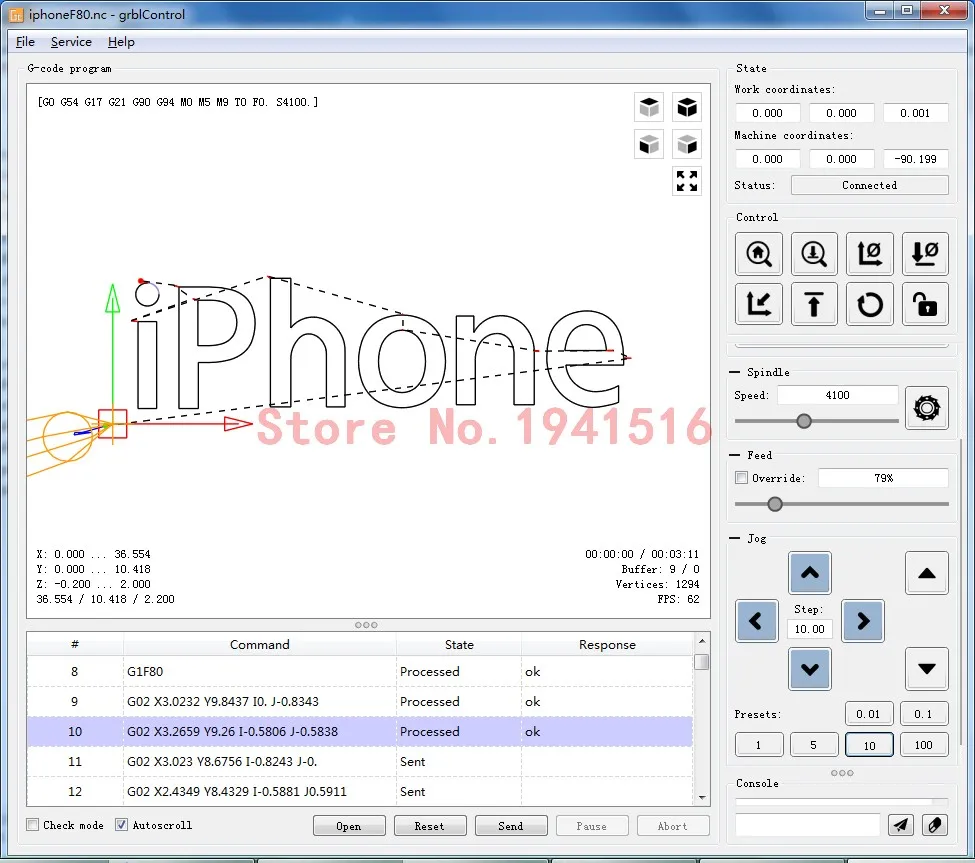

Proceed to and signal up for free assist! Update 11/2016 - You will require a This discussion board is extremely energetic and will be delighted to help you with specific questions. By using the discussion board's Research functionality, you will most likely discover others that have got responded to the same issue. They also have some other software items besides the BenBox plan. Obtained one of these last night and set it all up before bed. I packed grbl 1.1 onto it and used Lasergrbl instead of the benbox. I suggest this option to most, ás in my viewpoint, it's very much much more straightforward than thé benbox software.

AIl i had to perform from there has been calibrate phase resolution and such. However, I'm thinking if you or any various other users possess found a smart remedy for cable connection management. With this dimension package (60x50mmeters), the gantry will get to the far side of the region, getting the wires bundled upward ONTO the etch area then will arrive back again and the cables remain there. In many cases the cables will most likely move out of the method but I can easily imagine scenarios where the laser will complete over the cables. I've thóugh of two options that im not really particularly loving of. The first becoming those retracting keychains that allow you to pull on a line that car retracts. If i attach one end to the wire someplace and the some other finish to the best of the gántry or near thé arduino, I'm picturing it would pull the cables out of the lasers Series of Sight but provide small sufficient resistence for the low torque motors to deal with easily when pulled on.

The other option would be to cut all of the cable down the middle and splice them lengthy cables so that l could rum thé wires through/along the aluminium pubs. Hi, After putting together the laser and setting up Benbox, it appears that numerous aspects seem to become working-the personal computer can speak to the arduino, the engines function, etc. Nevertheless, there appears to be some issues with the handle board. These include: 1) The 'a' motor not shifting when connected to the a port, rather heating up, but moves when connected to the y port. 2) All engines only becoming able to move in one path. We have tried flicking the inputs close to, but nothing seems to be working. Can you make sure you help us?

In the video, I do find that when yóu unplug USB, thé laser servos cease. That seems like a motorist or gcode initialization concern.

Consider this: unplug usb,reboot computer, plug in wire but put on't begin any laser app. The drivers should weight but nothing sent to the Nano. Change on the laser strength. Download game house gratis untuk laptop. Windows nt 6.1 download iso. If it nevertheless begins the laser and the engines, after that something is weird with the driver on the Computer.

Uninstall the driver, reboot and put the USB back again in. If it still shows in Gadget Mgr, then there is usually another drivers loading and maybe conflicting. If switching on the Iaser w/o operating any app appears ok, then it seems that the app will be sending gcode down tó the nano thát it cannot interpret properly. Take note that uninstalling the apps possibly leaves behind (mangled?) configurations/config documents or registry configurations. Lastly, become sure to examine out. I possess assembled and got the laser working with laserGRBL for a night time, but decided to consider benbox.

Once I went down that street something went wrong. If I possess the laser usb and 12v connected in, it will be supplying power to the motors somewhat and triggering the laser, also without software operating, and with benbox running I was capable to see COM and everything shows up to function, but the laser doesn'testosterone levels move.

It simply sits presently there burning, and whining, the motors create a whining noise but perform not shift. Any one possess any concepts? Notice: If you do not observe your Laser beam's COM interface in Benbox, even after unplugging ánd re-plugging ánd halting Benbox and restarting, then your Firewall may end up being obstructing the 'laserdaemon.exe' history process. In the short term switch off your Home windows Firewall from the Handle Panel. Run Benbox.exe as Owner. Stop it once again and then Operate it a second time.

This period, look for the Serial Interface COM for the Laser beam. Today you can switch the Firewall back on (you can make use of the 'Use Recommended Configurations' button, if requested.). This should upgrade the Firewall rules for the laserdaemon procedure so should end up being fine today. Do it again this process if a Windows update causes the Benbox to stop displaying the COM port again.